ATCO HERD Dust Collection System

- Service: Mechanical

- Location: Edmonton, Alberta

- Specialty: HVAC

Project Summary

ATCO is Alberta’s largest natural gas utility, serving over one million customers across the province. Their South Edmonton Facility contains extensive metal and woodworking shops that are used to fabricate components for various ATCO projects. Lexus Engineering was engaged to design a dust collection system for the 1,600 sq. ft. woodworking shop, which up until this point contained a basic system consisting of bag collectors for only some of the machines.

Project Goals

The goal was to design a permanent and comprehensive dust collection system that would a) serve both stationary and moveable machines, of different styles, b) recirculate filtered air back into the shop, eliminating the need for a make-up air unit, as well as c) allow for easier clean-up and collection during various shop uses. At the same time, the system had to be designed to strict safety standards to minimize any explosion or fire hazards that may occur within a centralized dust collection system. The shop’s heating system needed to be redesigned to limit fire and explosion hazards that come with having exposed flame heaters within a dusty environment.

Our Solutions

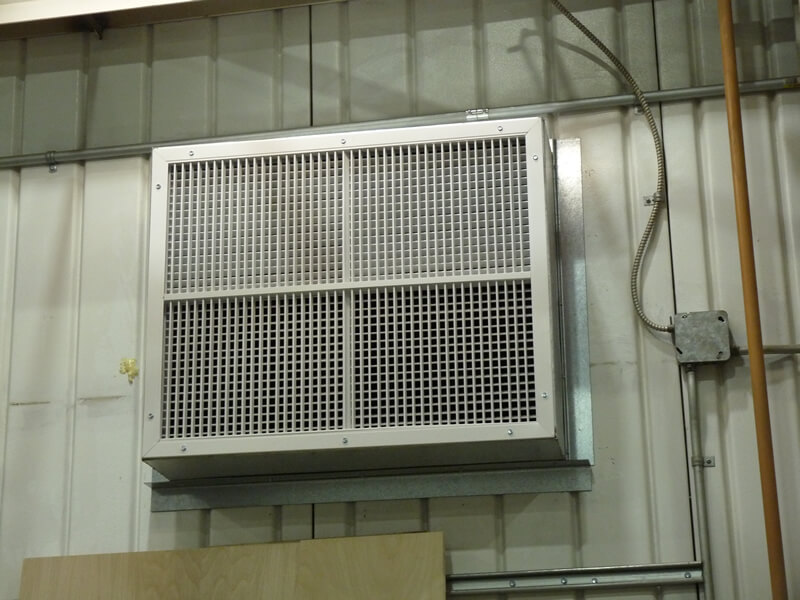

With careful consideration, we addressed every part of the system. Starting with appropriate sizing of the dust collector, taking into consideration the estimated amount of dust generation from every machine based on typical shop uses. The dust collector was installed in a storage building outside of the shop, which minimized the noise given off by the machine. Moving on to ductwork layout and sizing, making sure that the dust particles will remain suspended in the ductwork (Fig. 1) on their path to the dust collector. Due to the excessive volume of air being drawn out the building by the collector, a building depressurization condition was of concern. To eliminate the need for ‘make-up air’ we used a dust collector that recirculated the air back into the space upon filtering it (Fig. 2).

We specified a combination of permanent connections to stationary machines (Fig. 3), as well as adjustable adapters in central locations that would serve the moveable machines (Fig. 4), a hose reel with 25’ of flexible hose (Fig. 5) to be used when a trailer is brought into the shop for interior modifications, and a floor sweep collector (Fig. 6) to absorb any loose dust that will be swept periodically.

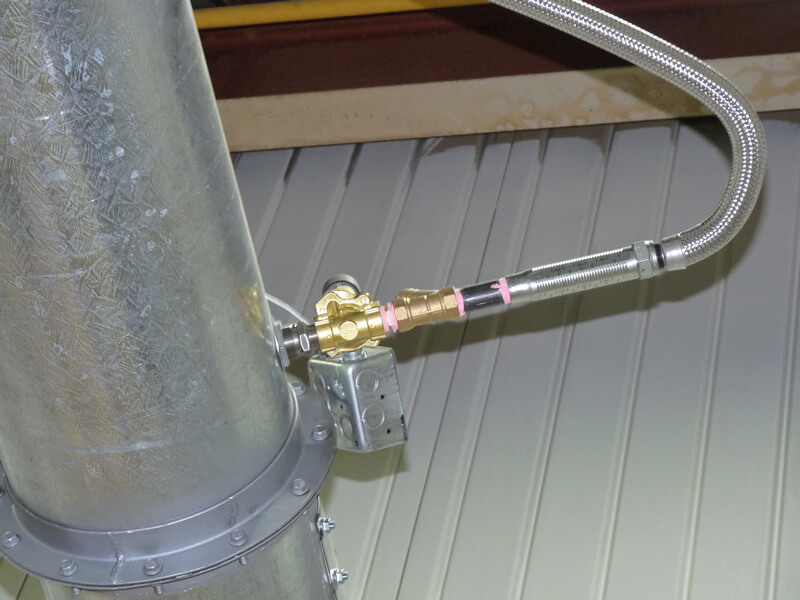

Next, the system had to include a series of safety measures, namely: a spark detection system, complete with a water-based fire extinguishing (Fig. 7) system designed for the ductwork to prevent any sparks from making their way to the collector. Furthermore, in the case that this fails, an explosion blast door (Fig. 8) is built into the dust collector to relieve pressure during an explosion within the dust collector. Similarly, an explosion-proof backdraft damper (Fig. 9) in the ductwork will stop the propagation of that explosion into the shop area.

The dust collector and spark detection system were supplied with a dedicated control panel (Fig. 10), which included a fire alarm in case heat is detected in the duct, signifying a fire. Lastly, the existing high-intensity infrared heaters in the shop were replaced with ‘separated-combustion’ gas-fired unit heaters (Fig.11), which contain an isolated combustion chamber that draws air from the outside, rather than from the space.

Result

Within a quick project turnaround, Lexus Engineering was able to design a sophisticated, cost-effective dust collection system that is assured to improve the air quality, cleanliness, and safety of the woodworking shop at the ATCO HERD facility in Edmonton.

Codes: NBC2019AE, NFPA 68, NFPA 13

Recent Posts

Ways to Improve Your Indoor Air Quality and Energy Efficiency – HRV or ERV

Ways to Improve Your Indoor Air Quality and Energy Efficiency – HRV or ERV If you want to improve the indoor air quality and energy

HVAC Energy Saving Products

HVAC Energy Saving Products In today’s energy-conscious world, it is crucial to optimize HVAC systems for efficiency and cost savings. Lexus Engineering can help you

Introduction to the HeatSavr Liquid Pool Cover

Introduction to the HeatSavr Liquid Pool Cover HeatSavr is an innovative liquid pool cover solution that helps conserve energy, reduce water evaporation, and maintain optimal

Endotherm, a Revolutionary but Simple Additive is an Energy Savings Leader

Endotherm, a Revolutionary but Simple Additive is an Energy Savings Leader Endotherm can revolutionize your heating or cooling system with its advanced formula. It enhances

Discover the Power of Efficiency: Uncovering Savings With an Energy Audit

Discover the Power of Efficiency: Uncovering Savings With an Energy Audit Are you and your business looking for ways to save money and enhance

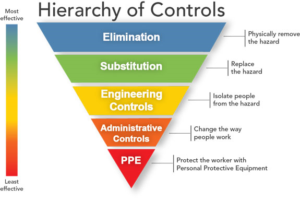

Hierarchy of Controls

There is a popular misconception that PPE is the most effective way of controlling exposures, but Engineering Controls are more effective. Overview Controlling exposures to

Contact Details

![]()

Headquarters:

Unit 208, 8716-48 Avenue NW

Edmonton, Alberta

T6E 5L1