CHP for Business Solutions

Combined Heat and Power (CHP) is the simultaneous production of electricity and thermal energy

for use in heating, cooling, or other processes.

Boost Your Business with CHP

Lower Energy

Costs

CHP can drastically reduce your energy bills through efficient energy production and use, saving you thousands of dollars every year.

Increased

Reliability

CHP allows you to generate your own power on site, giving you more control over your energy supply and enhancing your grid reliability.

Reduced

Environmental Impact

By reducing your reliance on grid-supplied electricity, you can lower your business’s carbon footprint and contribute to a cleaner, more sustainable future.

CHP Technologies

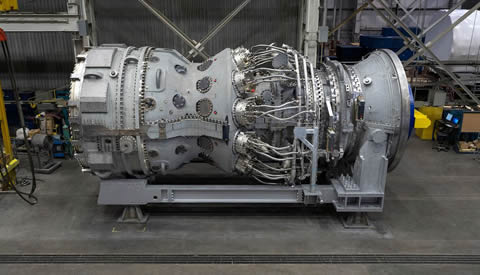

Gas Turbine CHP

Uses hot gases produced by the combustion of natural gas to drive a turbine, generating electricity and heat.

Microturbine CHP

Converts natural gas or other fuels into electricity and heat through a high-speed combustion process, ideal for smaller businesses.

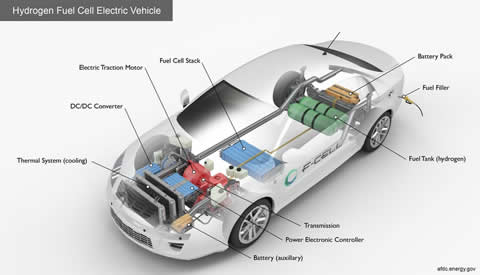

Fuel Cell CHP

Generates electricity and heat through an electrochemical process using hydrogen, natural gas, or biogas as a fuel source.

Steam Turbine CHP

Uses high-pressure steam to generate electricity and heat through a turbine, with the added benefit of producing steam for other processes.

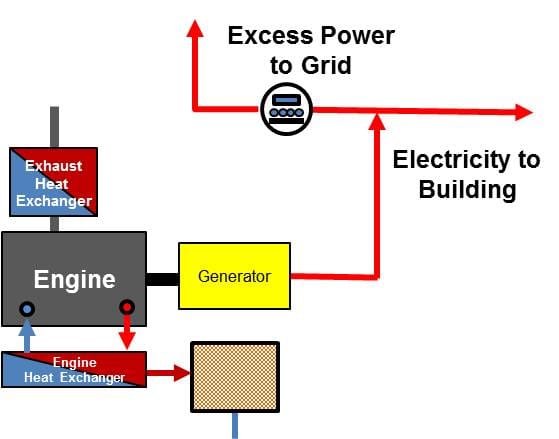

Internal Combustion Engines

Spark ignition engines for power generation use natural gas as the preferred fuel, although they can be set up to run on propane, gasoline, or landfill gas. Current generation natural gas engines offer low first cost, fast start-up, proven reliability when properly maintained, excellent load-following characteristics, and significant heat recovery potential.

Evaluating Economic Viability

To assess the economic feasibility of a possible CHP project and compare it with other energy options, two common methods are payback analysis and life cycle cost (LCC) analysis. Both methods involve calculating the costs, revenues, incentives and savings of the project, as well as the costs of a baseline or alternative scenario, and generating net annual cash flows (pro forma). More advanced analysis can also include state and federal incentives such as tax credits or renewable energy attributes if applicable. The main difference is that LCC considers the whole life of the project while simple payback only considers the cash flows before the payback date and ignores the ones after.

Implementing CHP: Key Considerations

1. Energy Needs

2. Space and Infrastructure

3. Financing

4. Regulatory Requirements

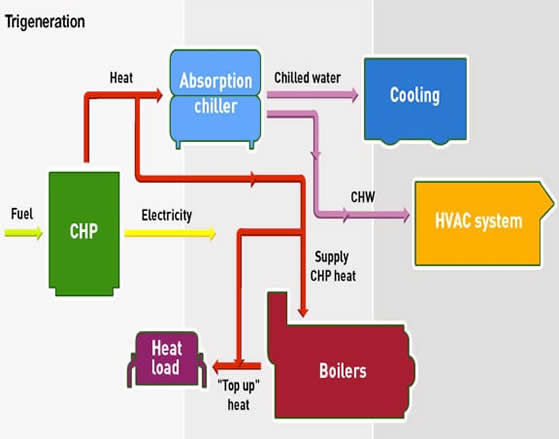

Tri-Generation

Internal Combustion Engine

Real-World CHP Success Stories

1. Humboldt Aquatic Center Humboldt, Saskatoon

2. Calgary Airport

3. Alberta Pork Producer Hartland Colony CHP installation helps farms offset carbon and energy costs

Cost Savings and Environmental Impact of CHP

Cost Savings

Environmental Impact

Conclusion and Recommendations

CHP is a smart choice for businesses

Explore CHP options for your business

Partner with Lexus Engineering

Contact Details

Get in Touch

![]()

Headquarters:

Unit 208, 8716-48 Avenue NW

Edmonton, Alberta

T6E 5L1